BIOGRINDER

Biogrinder

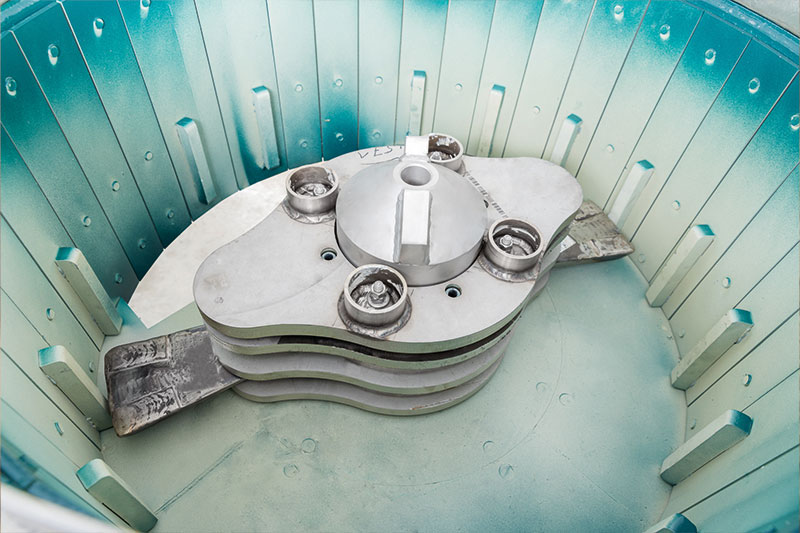

We offer the BIOGRINDER in two sizes and several motorization options, which allows optimal adaptation to your biogas plant. The unit is individually adapted to your needs by equipping it with a different number of hammers or counter blades.

- Easy integration into your existing biogas plant

- Feeding of a wide variety of materials, even the most difficult ones

- Insensitivity to impurities

- Low wear

- Accelerated gas production

- Stable fermentation process

- High energy efficiency

- Continuous process

- Future-proof investment

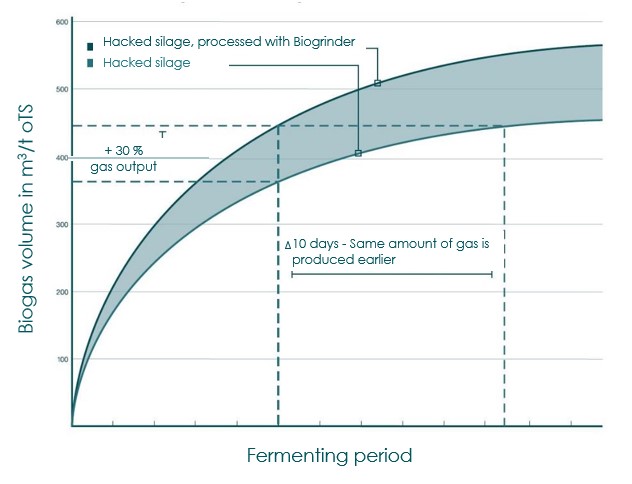

Higher and faster gas yield

The Biogrinder effectively mechanically shreds the organic feedstocks before the fermentation process. This accelerates the gas production and significantly increases biogas yield.

Feeding of the most diverse and difficult materials

The BIOGRINDER enables the feeding of field residual crops, difficult types of manure (e.g. poultry manure) and organic waste into the biogas plant, thus ensuring great raw material diversity and high profitability. This is how you remain flexible despite changing market conditions and legal frameworks.

Reduced retention time in the fermenter

The BIOGRINDER mechanically shreds the input materials via impact and shear forces instead of cutting them up. This increases the surface area of the biomass and thus also the attack surface for bacteria, which enables faster and more efficient decomposition in the fermenter with a shorter retention time.

Avoidance of floating layers

Rotor-driven impact tools in the machine defiber the material within seconds. This is how floating layers are avoided during the stirring process.

High throughputs

The use of a wide variety of raw materials in the Biogrinder and its defibering mode of operation optimally breaks down the substrate and ensures higher throughputs.

Insensitive to impurities

The bladeless principle is insensitive to metal parts and stones.

Mobile plant

Flexible use

Reliable quality

Fixed plant

Flexible use

Reliable quality

Information

Thoroughly shredded. Decomposed faster.

The Biogrinder refines your residues using a sophisticated defibering system. This increases the attack surface for bacteria and thus produces more efficient, faster and significantly better biogas. Respond flexibly to changing market conditions in the long run. The Biogrinder processes different raw materials and ensures continuous throughput. The plant will pay off within a very short time.

Results of the study by the University of Hohenheim

- Processing has a positive effect on the gas yield

- Mechanical treatment leads to an increase in the specific methane yield of up to 40% in practical trials.

- Mechanical pre-treatment of manure is mandatory