system solution agriculture

Biogrinder for farmers

Rotor-driven impact tools shred the material within seconds. This increases the surface area of the biomass and thus the attack surface for bacteria, enabling faster and more efficient decomposition.

The bladeless principle is insensitive to metal parts and stones, which occur, for example, in the processing of sugar beets.

Areas of application

Areas of application

BHS BIOGRINDER 08 with 55, 75 or 90kW and an impact area diameter of 1000mm, for large plants with high throughputs and the most difficult material.

- horse manure

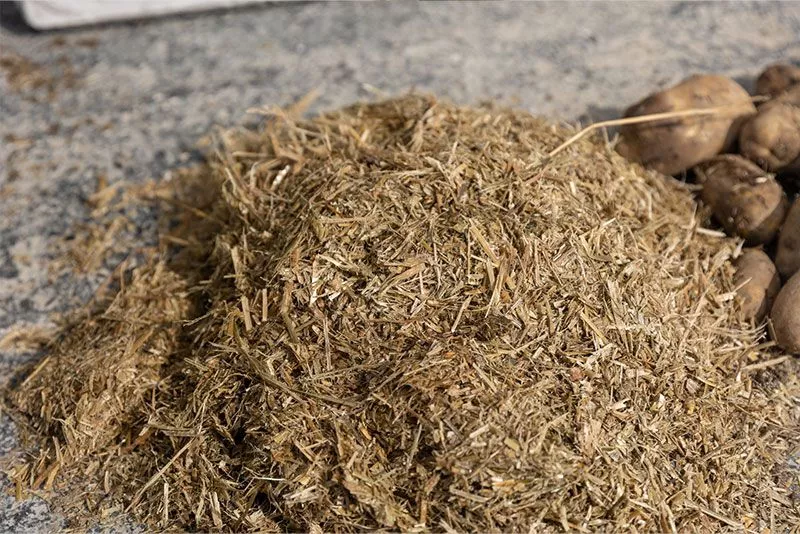

- corn straw

- sugar beet

- green rye

- grass silage

- Residual crops / Crop residues

- Cereal straw (also in bales)

- Dry chicken manure (HTK)

- Separated pig manure

- Whole plant rye silage

- Corn silage

- and much more

Thoroughly crushed. Decomposed faster.

The BIOGRINDER enables the feeding of field residual crops and difficult types of manure (e.g. poultry manure) into the biogas plant, thus ensuring a great variety of raw material and high economic efficiency. The substrate can be broken down optimally, because the BIOGRINDER mechanically shreds the input materials via impact and shear forces instead of cutting them up. This increases the surface area of the biomass and thus also the attack surface for bacteria, which enables faster and more efficient decomposition in the digester.

- The economic efficiency of the biogas plant is significantly increased:

- Higher and faster gas yield.

- High throughputs

- Shorter residence time in the fermenter

- Less energy consumption (e.g. for stirring)

- Substrates with low market value become usable

- You also benefit from further advantages:

- Easy integration into existing biogas plants

- Feeding of various & difficult materials

- More stable plant management

- Insensitive to impurities

- Low wear

- Avoidance of floating layers

- Adjustment of the degree of digestion via the impact tools

We offer the BIOGRINDER in two sizes and several motorization options, which allows an optimal adaptation to your biogas plant.

With the BIOGRINDER as an efficient system for processing silage, field residues, poultry, horse or cow manure and organic waste, you remain flexible despite changing market conditions and legal frameworks.

We put energy efficiency into practice – with the BIOGRINDER!